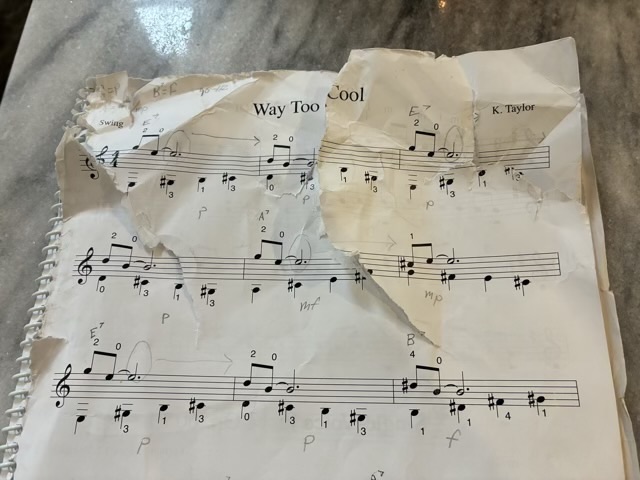

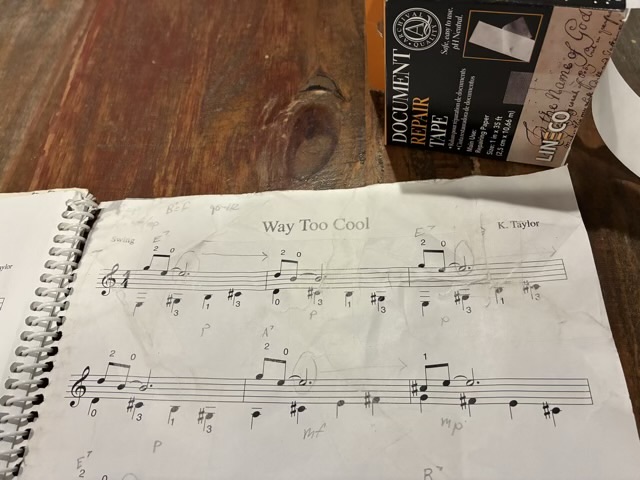

The roomba ate a page of my kid’s guitar lesson book. I’m not sure how the book ended up on the floor, but I suspect a cat.

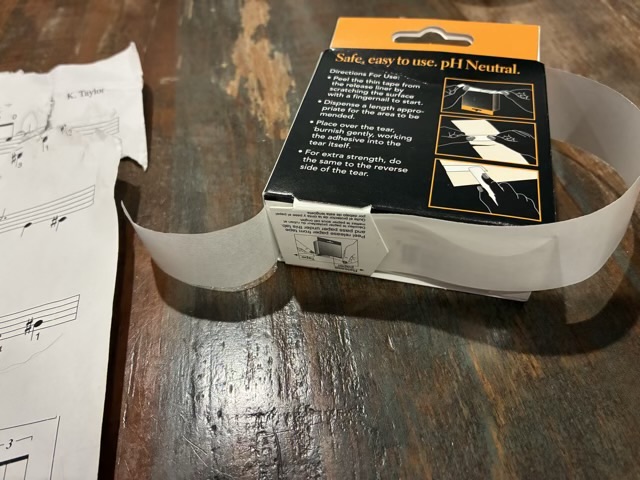

I ordered document repair tape, because I didn’t have any, and regular transparent tape applied at this magnitude would put further stress on the paper.

The hardest part was getting the tape away from the liner the first time. The box is conveniently set up to dispense the tape and manage the separation process. Getting is started is just a little tricky.

The tape doesn’t look transparent, but when applied to the paper the ink and pencil marks show through clearly. The tape is also thin, which is why it needs the backing, but is nearly imperceptible when applied. I made sure the tears lined up and where the paper split, that the ink side was visible. To reinforce the repair, I put the tape on the back of the page as well. The damage to the page was extensive, however, I was able to get it stabilized and usable, but not pristine.

Overall, I can recommend the document repair tape for quick repairs on paper that is referenced frequently, or eaten by the robot vacuum.