This poor shirt. I previously added crocheted elements, but didn’t like the way the sleeve crinkled in my elbow, so took off all the crochet.

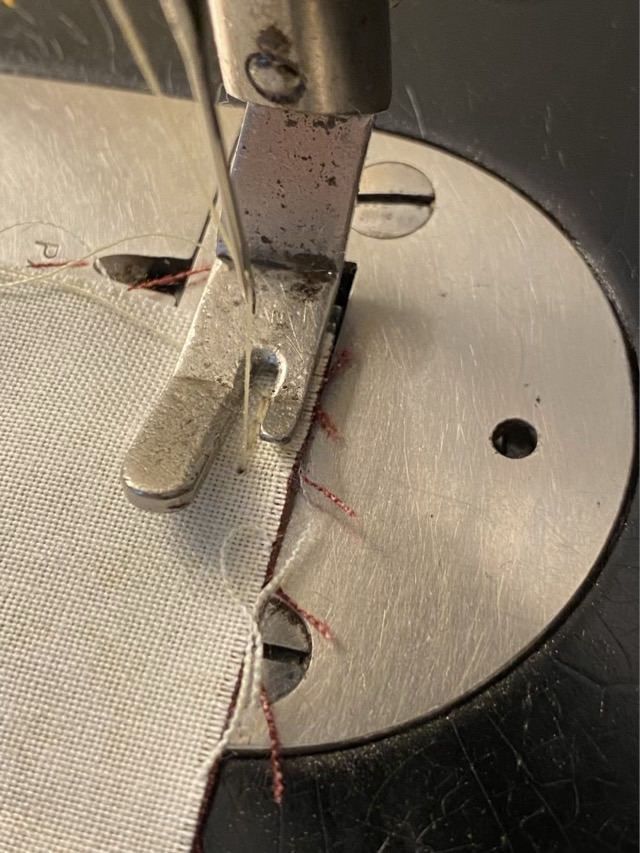

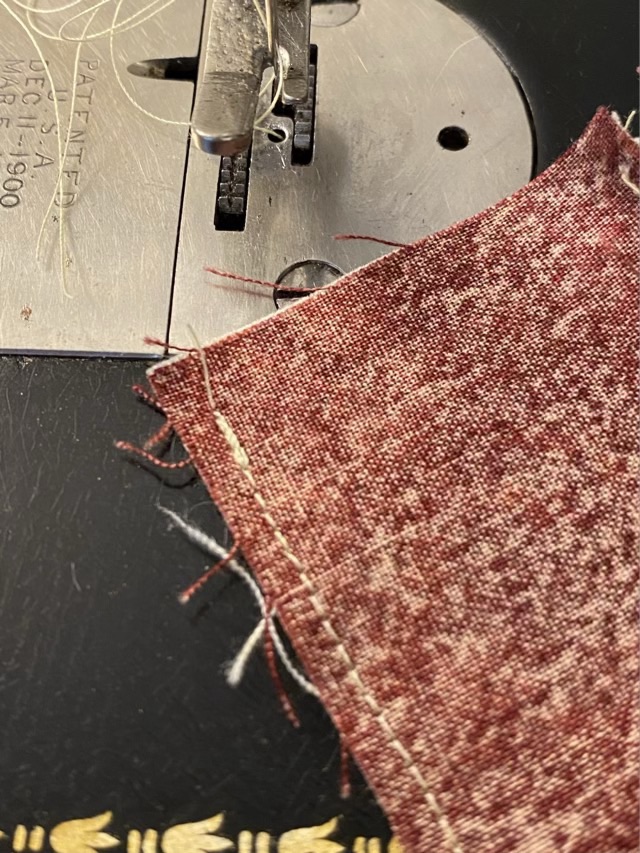

It hung sadly in my closet along with another shirt that had acquired stains on the front. Eventually they caught my attention again and I combined them. I used the black shirt as a base, removed the flutter sleeves from the purple shirt and sewed them to the bottom of the black sleeves by adding gathers to match the circumference. Then I took sections from the unstained fabric to make a hem extension, overlapping the sides in a petal formation and adding a narrow hand sewn hemmed edge. Honestly I hand sewed all the added bits, because I like to.