I replaced my recliner. The padding in the old one was breaking down, especially on the arms, causing pain and numbness in my own arm. I tried reworking the existing padding, and then replacing the padding, with no improvement. The recliner mechanism was also staring to go, again. (I did replace that a few years ago by ordering a new ratchet strip, but I even wore that out.) Time for a new seat, but what to do with the old one? It was not all leather, but did have some, could I reclaim it?

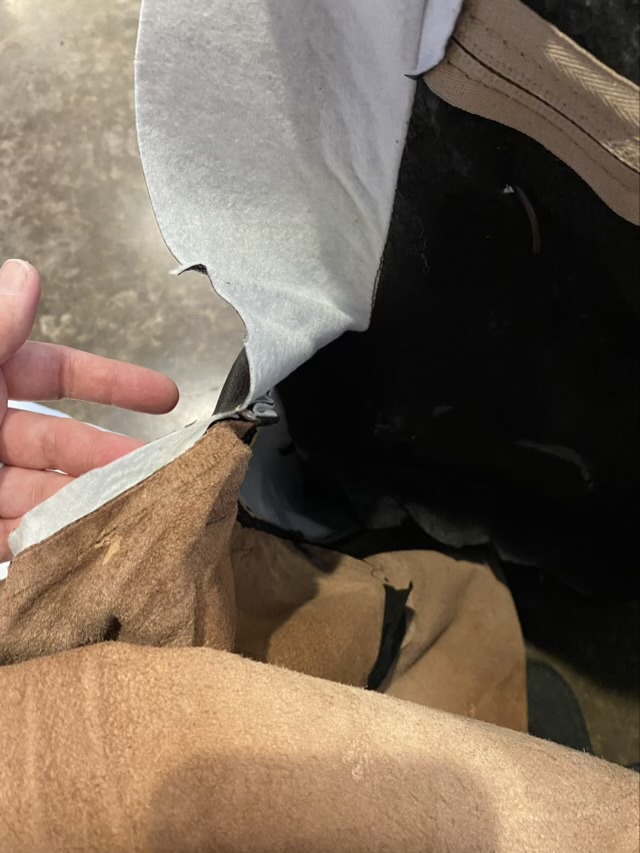

I took a pair of kitchen shears and went after the fabric of the chair.

Deconstructing was not terribly hard. Most of the screws were two sizes of Torx head, and I had the right size screwdrivers. I was appalled at the amount of cardboard inside the recliner, it was a thin sheet of that over the sharp edge of wood that was causing the pressure point in the arm of the chair; the curved slope was an illusion. The hardest thing to remove was the handle for the recliner action.

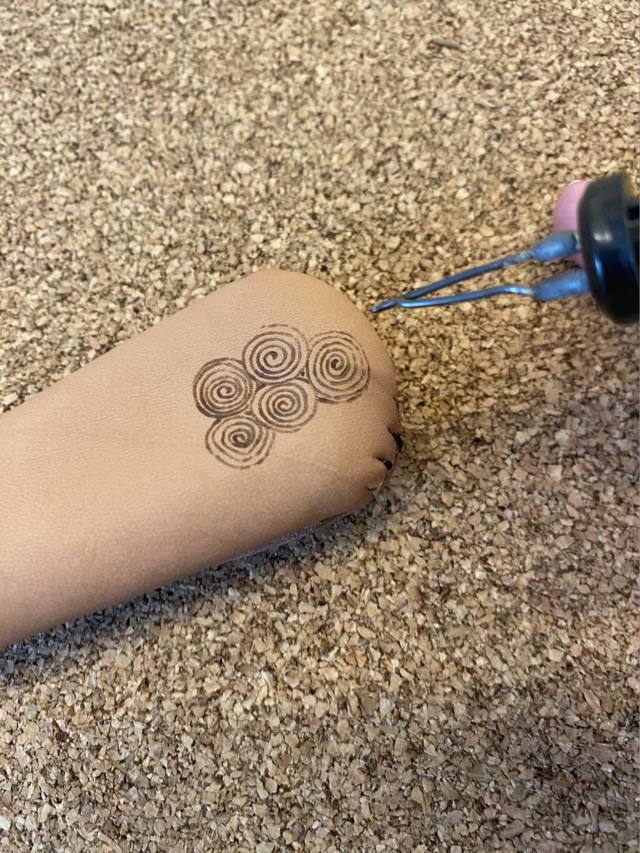

I’m thought about reclaiming some of the steel and springs, but I didn’t have a purpose in mind, and I don’t have the storage space for that much “maybe”. I used leather often, so I knew that was a valuable resource.

In the end, I reclaimed 2 pounds 9 ounces of leather and reduced the recliner to fit in four black bags, which could be put out with the other trash and not require a special pick up.