I recently used points to get a Clover mini loom. I have been using scraps of cardboard to weave samples of my spun fibers to go in my fiber journal, so this was an upgrade!

I started by following directions, amazingly, but the spacing of the tines were very wide and gave me a weft-faced weave, where the warp threads are completely covered by the weft yarn. This is the technique used for tapestry weaving, but not what I was looking for.

The next attempt I doubled the yarn in each slot by wrapping the warp yarn completely around the loom. This gave me fringe on top and bottom when it was finished, but the weave came out with both the warp and weft showing.

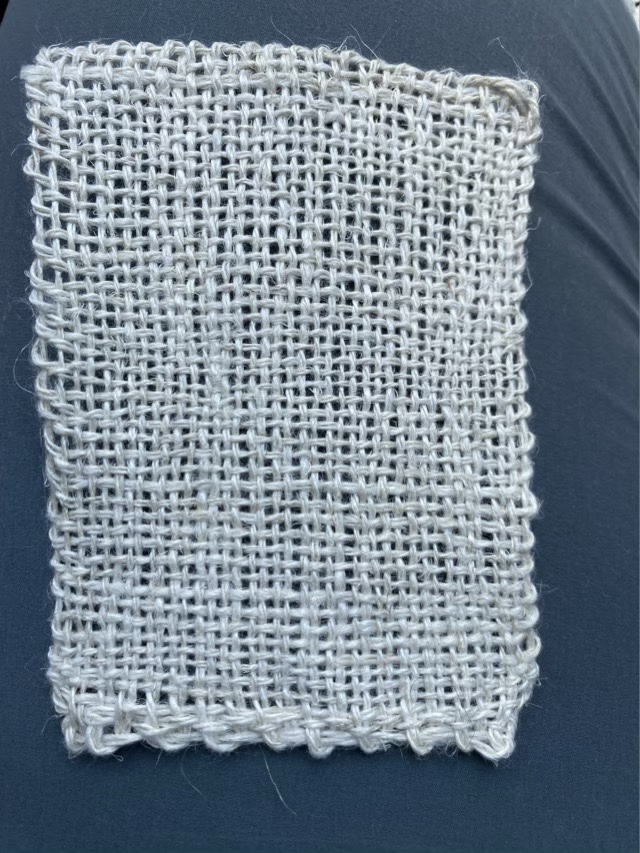

I moved on to my hemp yarn, and of course I forgot to take progress photos, but I doubled up the warp thread by making loops around the tines, resulting in a fringeless swatch. I found I didn’t need the twined first row to space the threads. It came out a bit wonky, but I am seeing process improvement.