I had the absolute privilege of spinning on a Great Wheel from the 1860s.

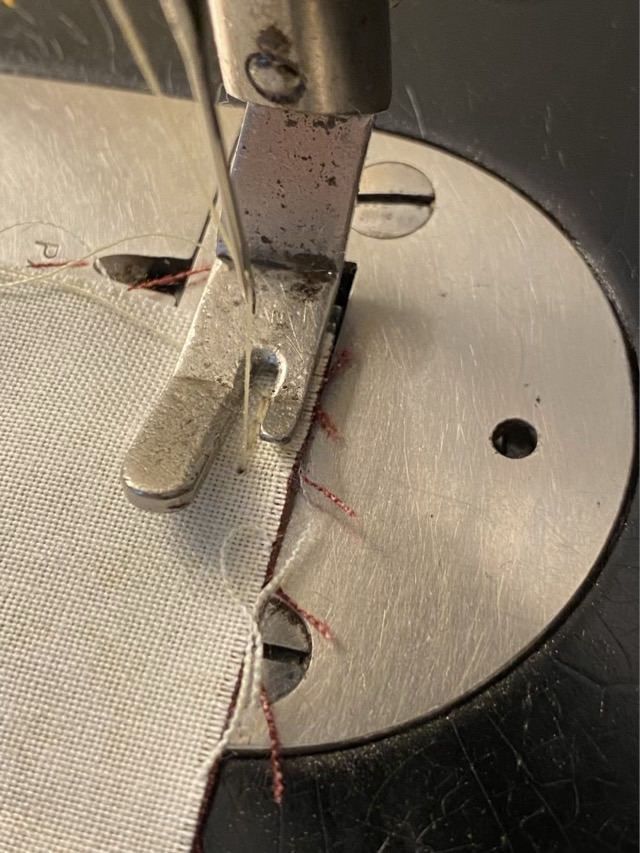

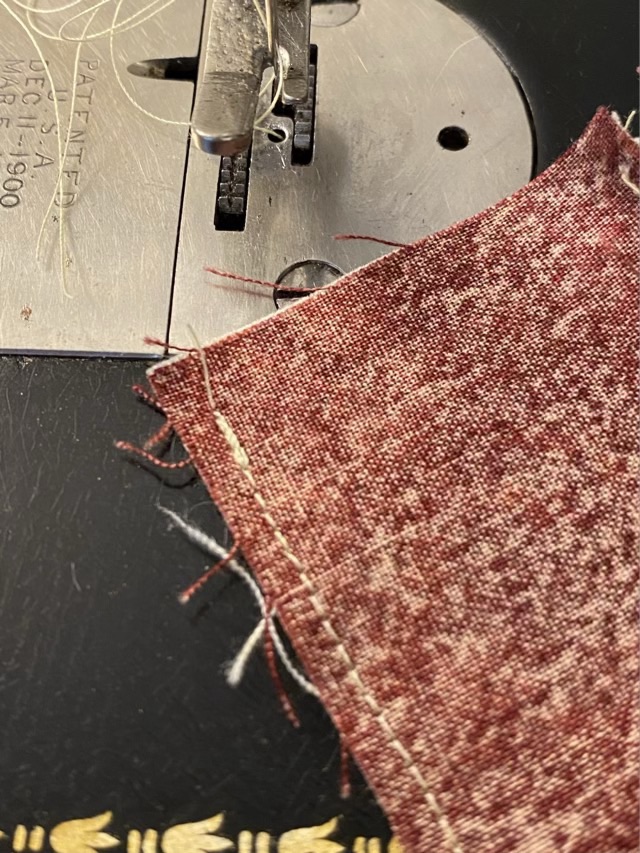

The wheel is older than the house she lives in (any item that is 165 years old deserves a pronoun upgrade, in my opinion.) The wheel was used to spin cotton, which was a primary staple in Texas at the time. She was in a private collection for many years, but was placed in the Man House as an honorarium to her former spinner. It is an appropriate placement historically and a valuable display for visitors to see this wonderful piece of human-powered engineering. I was the first to spin on the wheel for ten years, if I have my stories straight, and it was a joy. I did spend an equal amount of time spinning, adjusting the wheel with field-expedient fixes, and talking about the wheel. I took with me Texas Coop cotton sliver and spun two cops of yarn over six hours.

I like to keep these posts relatively short for this blog, so I’m going to spread the deep dive into my spinning experience out over several days!