I’m working on replacing the center part of my broken rolling pin. Marble is such a delicate and hard to repair material, so I am replacing it with maple (plus, I already have maple on hand). I cut a section of a 3” round maple blank (which is marketed as a baseball bat blank) to 15” in length, which is about 2” longer than I need, so after I turn it, I can cut off the marred ends. I used my center finder (that I blogged about yesterday) to find the centers of both ends, and made 1/4” pilot holes on my drill press. I was hoping to drill the center hole on my lathe, but my lathe isn’t that fancy.

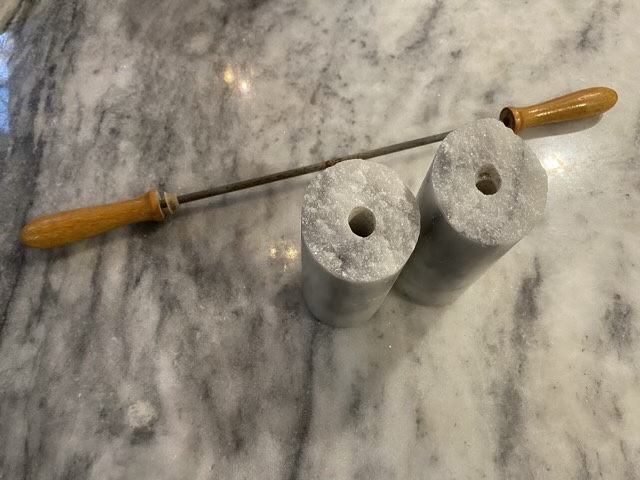

The drill press did well to start the holes, then I used a long 1/4” drill bit to drill halfway through on both ends. Miraculously, the two holes matched up in the middle with barely a jog.

After getting the hole drilled, I mounted the blank on my lathe. It was amazing how much work needed to be done to get the blank into round. It took me around two hours to get it roughed in and smoothed down. “Simple” straight cylinders are not simple to turn! I sanded down to 400 grit, then cut off the ends with the chop saw.

I cleaned up the steel rod and nylon flanges from the old rolling pin and tried them out. The fit was a little too tight, so I reamed out the hole with a 3/8” bit, and indented the ends about a 1/4” with a 1/2” bit to accommodate the flanges. It assembles and works! Now to “art” it, as my husband says.

(Part 3 of 8 in this blog series)

Happy Mother’s day to all those that mother! I’m trying out a new format with this series of posts, and didn’t plan for holidays. Oops. Live and learn. This too shall pass. Fussy babies go ni-night. (Getting in my Mom quotes.)