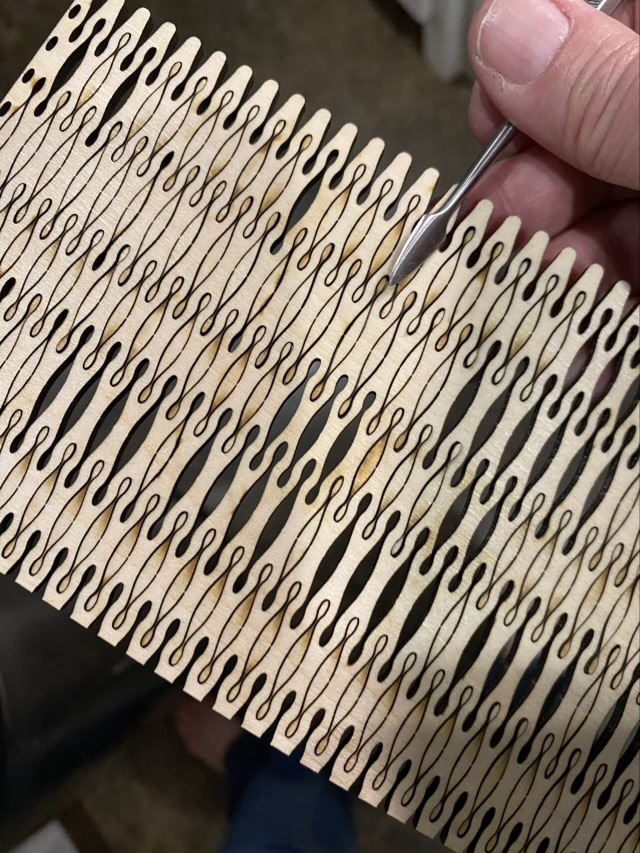

Making kerfs, small straight cuts, in thin plywood allows the wood to bend without breaking. Those kerfs can also be decorative. I found free patterns on an Instructables post, downloaded them, and used the basic building blocks to make an SVG file for a round dice cup. The SVG file was built with sections of the rounded pattern, which resulted in incomplete cuts only a fiber width thick, but enough that many of the cutouts had to be manually ejected (dental tools or long thin carving tools work well for this).

I mentioned that I don’t like butt joints, so I added lace holes along the edge and secured the join by lacing with leather cord. I then measured the diameter of my cup and cut a circle of wood to fit inside the bottom. This is a different kind of butt joint, so I also cut a piece of recycled leather (thank you old recliner) with holes spaced to line up with the gaps in the sides. I glued the leather to the wood and used the same leather lace to sew around the edge of the base.

I used my go-to finish, Howard’s Feed-N-Wax, which was problematic. The wax became wedged in the small decorative curves and was very difficult to rub into the surface. Some time in the oven on low melted the wax, but I think for the next project I’ll use light coats of a spray finish.

This was an interesting project that resulted in an unusual object, but not one I think I’ll repeat. I will take elements of this piece and apply them to other ideas.

Experiments continue.