Oh dear. I decided to see what my WIP (work in progress) count was up to. Hm. I’ll share them here as a kind of accountability, although I’m not counting the ball of napkin twine in the glove compartment of my car that is for emergency craft use (that project doesn’t need an end). Nor am I including the fiber survey that also ongoing.

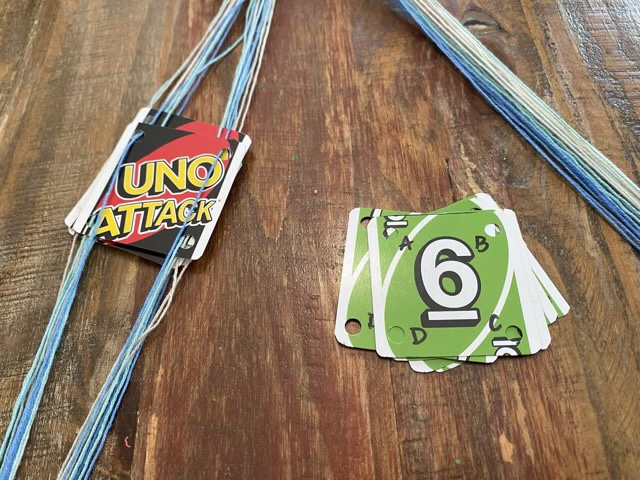

Developing a 3D printed spindle is my oldest WIP. I’m still working on the head breaking issue, but with the help of the printer, I feel we are nearer the end than to the beginning of this project.

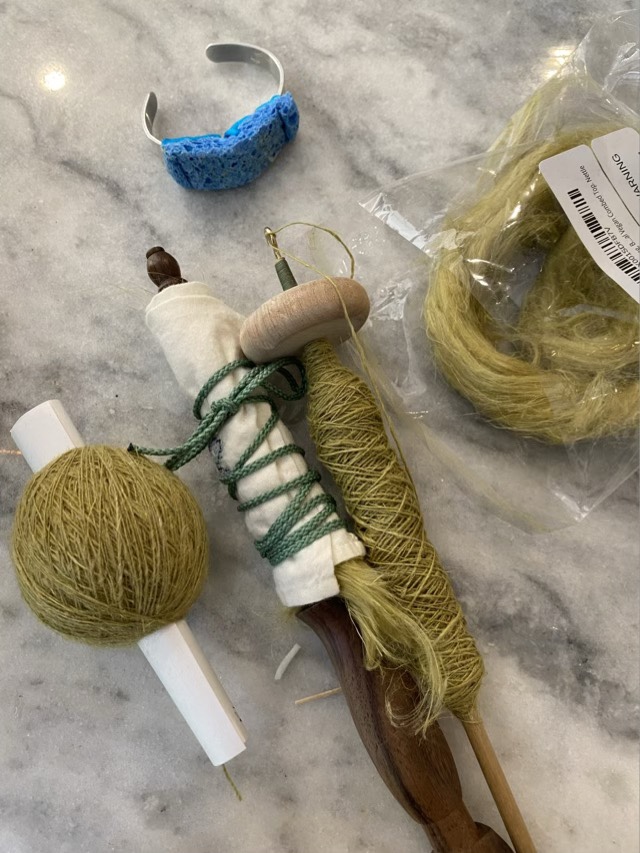

My sit and spin project on my vintage wheel is also nearing completion. I have a few hours worth of alpaca fiber left in the basket (the fiber in the blue bin is waste from combing). I have another portion of washed alpaca in queue.

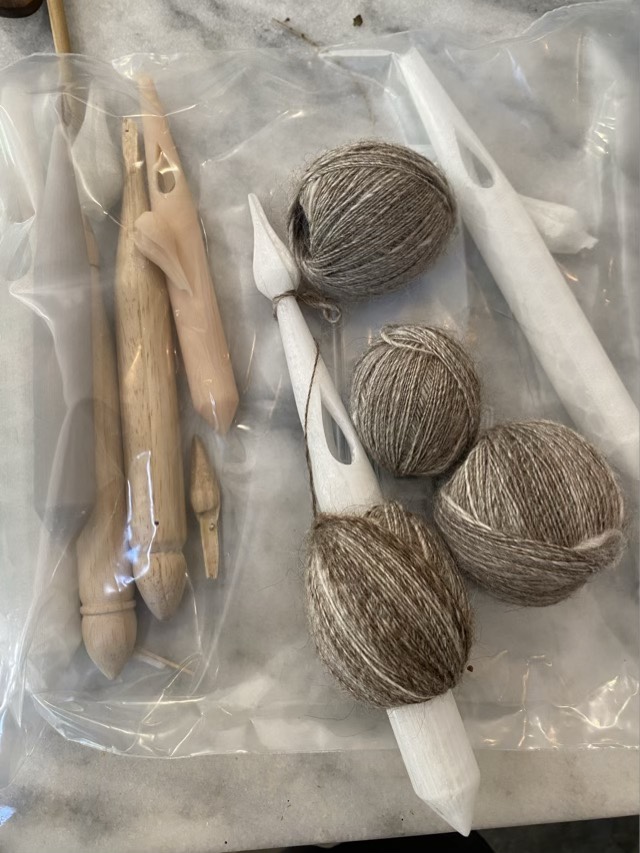

My walking spinning project involves my first taste of flax spinning. The roving preparation is an odd one, but I’m finally getting the trick of it. I maybe have two or three walks left to finish the singles, then I still need to ply and finish the yarn.

My rainbow scarf knitted with the Brioche method became a car project a while back. This was the best thing for this work, as I regularly knit for about an hour on it many times a week as I sit in the car rider line. I still have many hours left to go.

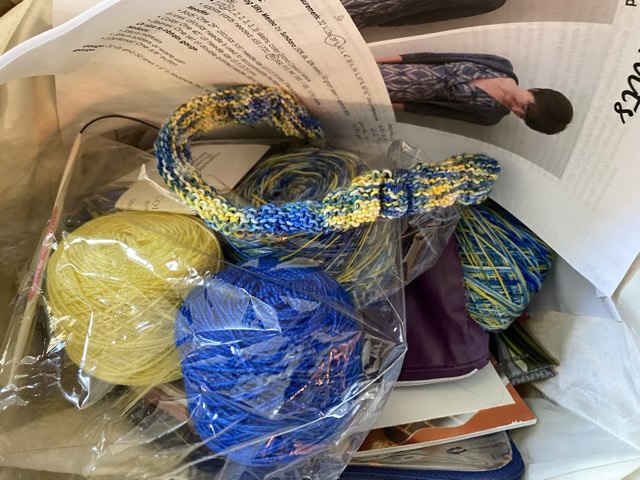

My newest WIP is a blue and yellow light-weight cardigan. This is a big step for me in knitting. I have made a couple of sleeved garments (as opposed to vests, scarves, hats, and gloves), but not many and they all have had sizing issues. I’m making the attempt again because I have grown as a knitter and am hoping the new skills will help. I have been planning this knit for months, but I hadn’t cast on yet, so it wasn’t an official WIP. It sits next to my chair at home.