I finished spinning singles from my two colors of Jacob’s wool roving.

I had extra of the silver colored roving, so I spun that up by itself.

Now to ply.

I finished spinning singles from my two colors of Jacob’s wool roving.

I had extra of the silver colored roving, so I spun that up by itself.

Now to ply.

My parents-in-law recently took a trip to South America and brought me back three hanks of beautifully spun and dyed alpaca yarn. I immediately set to opening up the hank to put on my yarn swift and use my ball winder to make a center pull ball, which is easier to use for knitting and crochet. I was met with resistance.

The hanks looked like what I was familiar with buying in the States, a large circle of wrapped yarn, twisted and tucked end in end for storage, but when I opened up the skein I did not find a continuous circle and it dawned on me that the wrap was different. I employed the arm power of my eldest to investigate.

The hanks were not wrapped in a loop, but instead used a figure 8 style wrap. Easy enough to handle with an extra pair of arms, but definitely not compatible with my yarn swift. My eldest obliged me by holding the yarn while I wound onto a wool winder.

Once I figured out how the hanks were wrapped, I was impressed with the way the figure 8 kept the strands in decent order. I am a firm believer that there are many ways, and I love finding out about other methods.

My mother-in-law also brought me a spindle; the spin on it is beautiful and it also is slightly different than what I’ve seen.

P.S. Sometimes I get my terminology swapped. The original post used the word “skein” in place of “hank”. I think I have fixed all instances.

I spun two spindles of Black Welsh Mountain fiber then moved on to other fibers, because with a 40 gram bag, that is about all I get. I actually had 4 ounces, and had tucked the bag up on a shelf and forgot. Finding it again (a black shadow at the top of a shelf) was better than finding money in the wash! So I wound the singles off of one spindle and into a center pull ball.

I had actually spun about 2 ounces (about 50 grams, so my estimate wasn’t far off), and since I had 2 ounces remaining I decided to spin some singles the opposite way. This challenges my brain and hands, but doesn’t result in the smoothest yarn, yet. The idea is that I can do some experiments with the opposite twists.

For my North Carolina grown cotton fiber page I had enough hand spun crepe yarn to twine a small pouch. I used a square of sanded eighth inch plywood as my form and twined until I was about square. To finish the bottom, I ran the warp threads up the opposite side of the bag.

After I wove in all the warp threads, I realized a probably should have knotted them, then wove them in. Since this bag will only be on display in a book, it won’t see heavy use, but it is something I need to remember for next time I twine a bag. The picture of the pouch looks skewed because there is a bias twist in the fabric. I noticed when I started twining that I was actually untwisting the ply, so I switched my twine direction, which reinforced the ply, but gave it extra twist energy. It should even out after blocking.

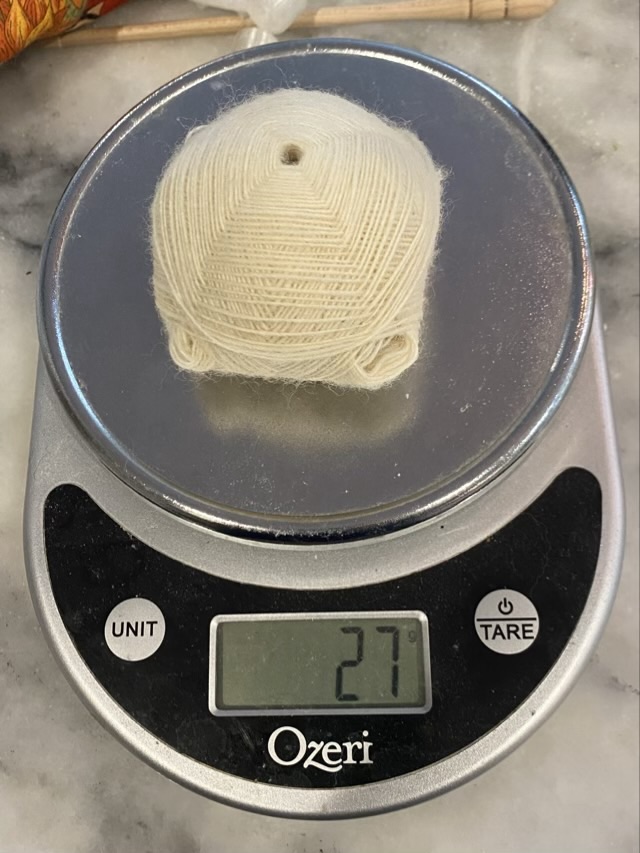

I’m spinning Southdown wool on a 3D printed Turkish style spindle. I decided to weigh my yarn turtles so I can match them (as much as possible) to make plying easier. I started with the weight of the spindle and the single spun yarn.

Then I removed the yarn and weighed the spindle for reference.

Then I weighed the yarn turtle.

I forgot that if you stop winding part way through a layer on a yarn turtle, the layer peels up. It really needs a full wrap to stay neatly in place while in storage, so I removed the unruly layer, used it to start a new turtle, and weighed again.

I have about 113 grams of Southdown roving, so I should get four turtles, if I track it carefully. It will take me awhile, I’m spinning during my walks, so only spin a bit at a time.