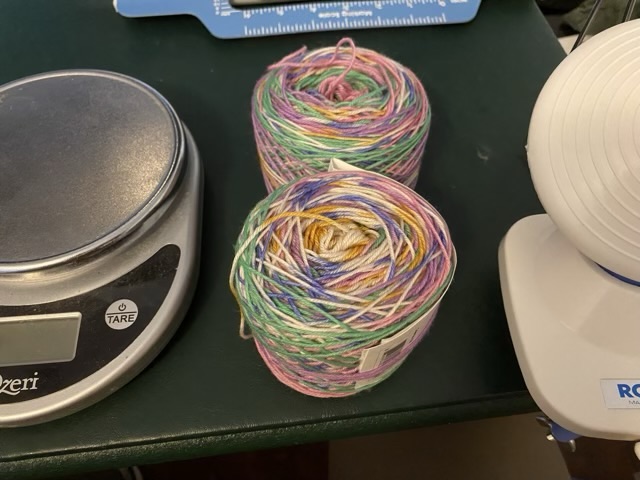

I found painted yarn at my local yarn shop! This yarn is self striping by having a precise color repeat. I don’t need my socks to be identical, but I don’t like knitting two socks from the same ball because of tangle and twist issues, so I divided it in two using a scale and a ball winder.

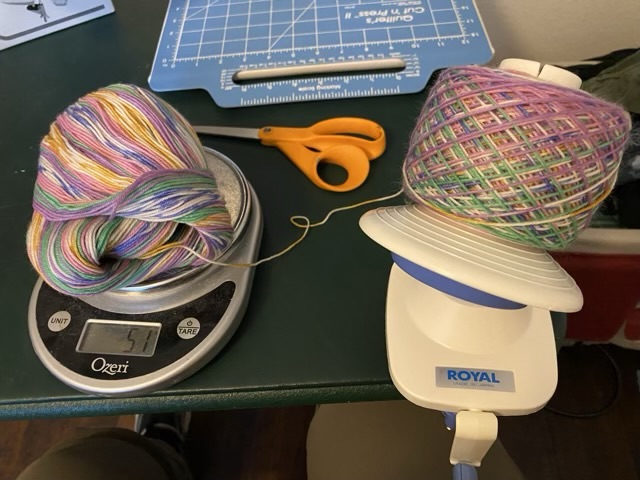

I place the full amount of yarn on a scale to get the total weight, then I wind my yarn into a cake using a Royal wool winder until the scale reads half the original. I cut the yarn, and start a new yarn cake.

It is harder to measure going from skein to cake because the skein is on an umbrella swift and the cake on a ball winder, both clamped to the table, but if you go a little past what you think is half, then weigh the cake, it is easy to wind off back onto the swift.