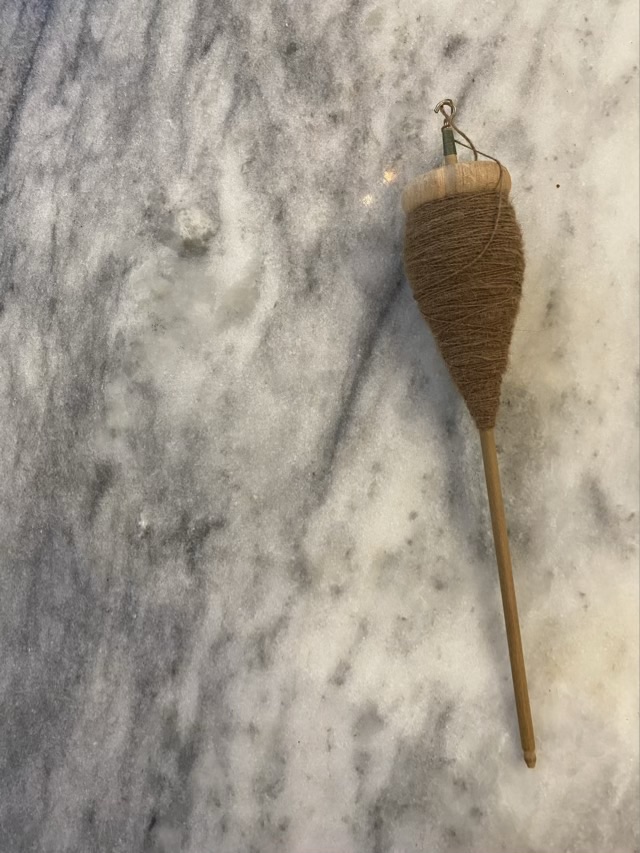

For my next spinning adventure I selected banana fiber (made from banana leaves) from my stash. It was already in my mind to consciously spin thicker singles, because my default spin size has been getting quite fine. It was a double challenge with the banana fiber which has about an 8 inch staple length (the length of individual fibers). Spinning fine would not be a challenge, spinning thicker was! To add to my challenge my fingers decided to spin the singles counterclockwise, opposite to how I usually spin. (Probably because I ply counterclockwise when I’ve spun clockwise, so my hands were already in ply mode.) The counterclockwise twist did not make the hook on my spindle happy, and it unscrewed in the middle of the walk and flew off into the grass. Hm. Undeterred, I switched to making a half hitch to secured the spun yarn.

I was pleased that the silk lashing I do on the top of my spindle shaft also serves as a security measure for the half hitch. Not only did I finish the walk still spinning, I continued to use the half hitch method for the rest of the spin over the next few walks.

I managed to spin slightly thicker, we’ll see how it plies up. The banana fiber has a stiffness to it, more like flax, and doesn’t need much twist to make viable yarn. It had a cottony feel to it, despite the long staple length. It was easy to spin, but I think if I spin it again I will load the fiber on a distaff rather than pull off sections of combed top roving.