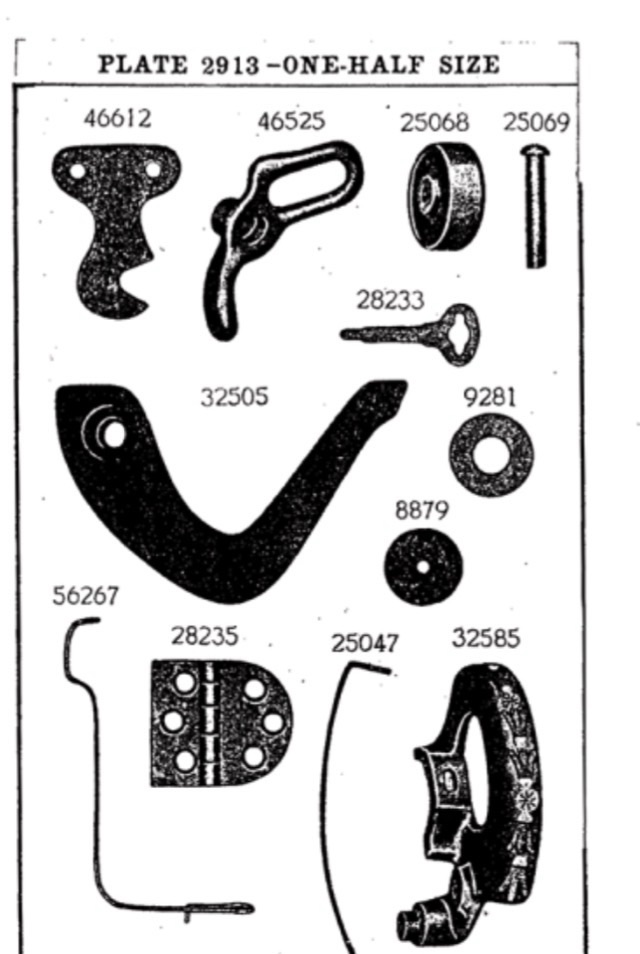

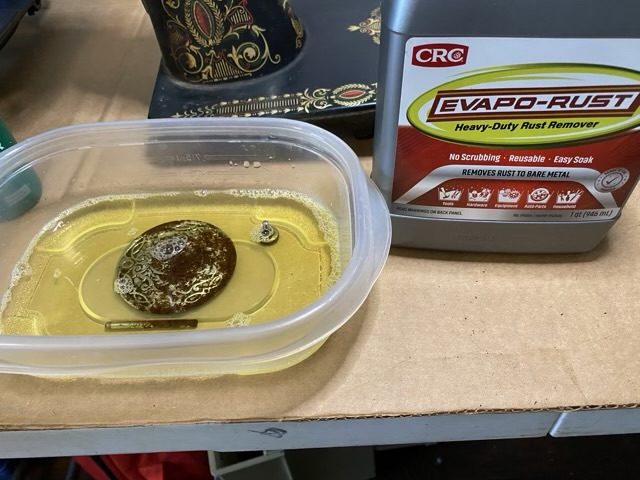

I thought the Singer model 66 was set at the tiniest stitch, so I’ve been gradually turning the stitch length knob, pictured below and marked with an arrow, to the left. This knob on both my machines was quite difficult to turn and needed extra sewing machine oil, and a wrench with the jaws wrapped in leather, so as not to damage the knob.

My assumption was wrong. Turning the knob to the left makes the stitches even tinier!

So now it makes sense that I have seen these knobs all the way screwed in, the longest stitch works well for sewing the most common fabrics. There wouldn’t have been much call for changing the stitch length, so more time for the knob threads to seize up.

I also figured out a way to “reverse” stitch on the treadle machine that absolutely does not have a reverse capability: I turn the fabric around. I sew a few stitches, bury the needle, lift the pressure foot, turn the fabric 180 degrees, lower the pressure foot, sew a few stitches back to the beginning, then turn again and continue with my seam. Here is a video. These stitches are so small I probably don’t need the extra reinforcement, but it makes me feel better.