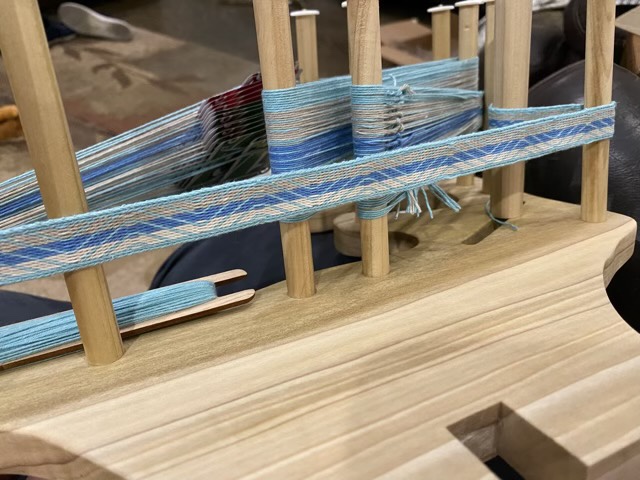

Time to test my inkle loom! I picked a tablet weaving pattern that had an easy 12 turns forward, 12 turns back progression for my test. I warped the loom with a cotton blend yarn in four colors. There are several ways to warp an inkle loom. For this first test, I did four strands at a time (one for each corner of the card), and used a square knot to tie the ends together.

I started the weave with four slips of card stock, as recommended by several weavers, both to get an even start and to leave room for fringe. I wove the tail back into the first few passes to lock it in.

One of the big issues when tablet weaving on an inkle loom is the buildup of twist.

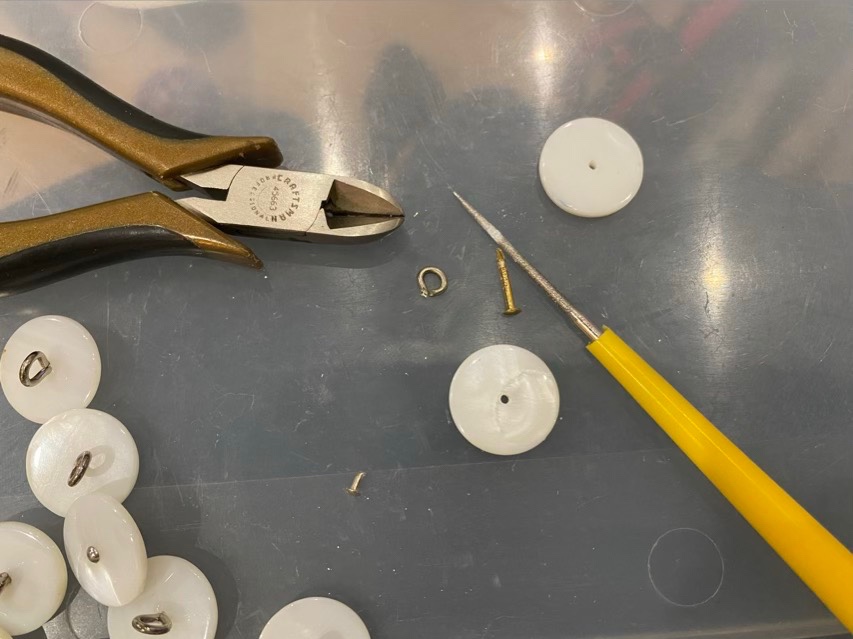

Traditional tablet weaving with a backstrap allows the weaver to comb out the twist (which I would still find an irritating process). Modern weavers will make use of swivel hooks and chase the twist out to the swivel, or use a balanced pattern the has the same number of forward twists as backward twists. I also found a card flipping method that allows turning to continue in the same motion, but flips the twist. However, it flips the diagonals on the weave as well. With a solid color border this change in direction is harder to detect, but I can still see it. Hm.

Aside from the twist issue, the weaving is going well. The tension post works, the pegs are solid (I have one peg that didn’t come out perfectly straight, but it doesn’t seem to harm the weaving at this width). Now to weave for awhile (but not too long because it goes fast).