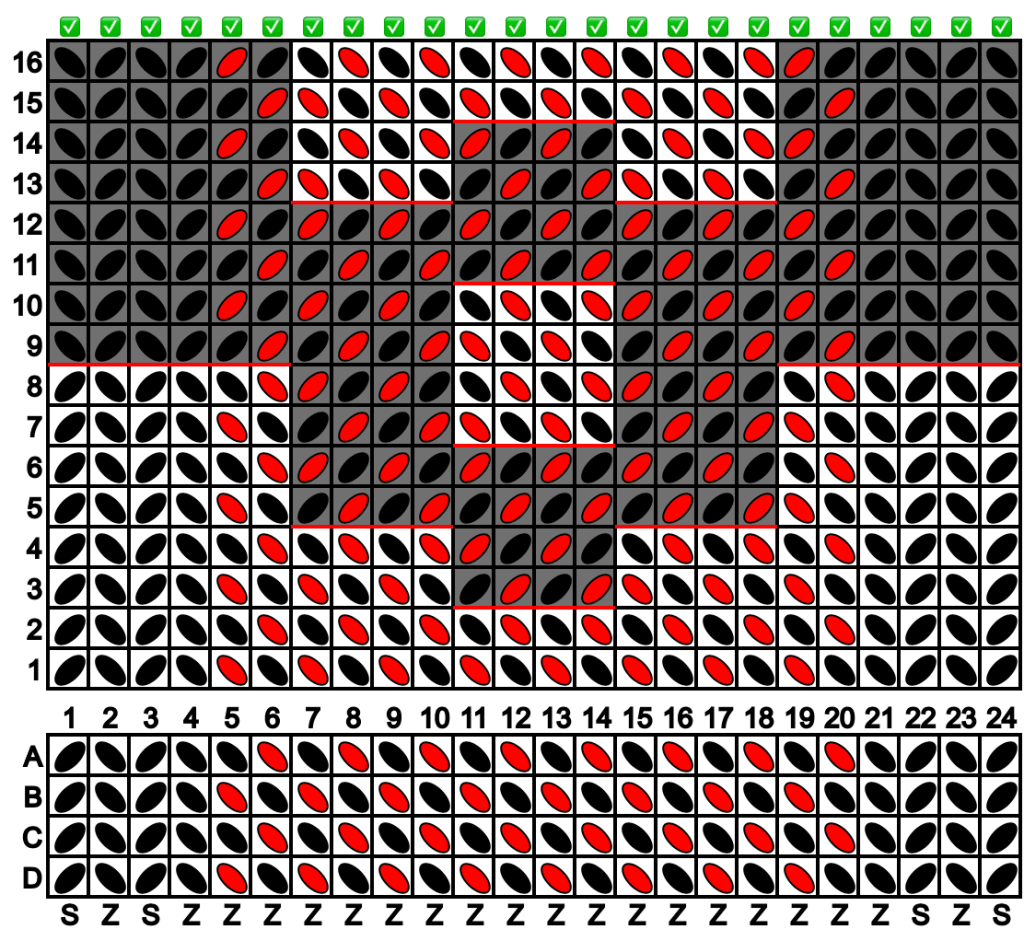

My Mom requested a stretchy woven watch band. I took one of the plain purchased bands she had so I had the hardware, and I purchased colored shirring elastic thread. I set up a 22 card tablet weave on my Inkle Loom using a pattern I found on Pinterest. An interesting thing about tablet weaving patterns is that the result changes depending on how the cards are turned. It took me a little time to figure out how the pattern worked, so I decided to make four different patterns on the same band, then cut them later. I also had quite a shock when I removed the band from the loom and the elastic contracted, creating different issues.

When I warped the loom, I didn’t pull the thread completely tight, it is quite elastic, but on hindsight could have loosened it up a little more. I did pull the weft thread taught. If someone is reading this to get hints on the how, I recommend trying a non elastic weft. On the final band three of the designs puckered strangely, one in the middle and the other two on the edges. I think this is due to the tension or uneven tension on the warp and the pattern. It was difficult to get an even pull on all 88 threads when it was so elastic.

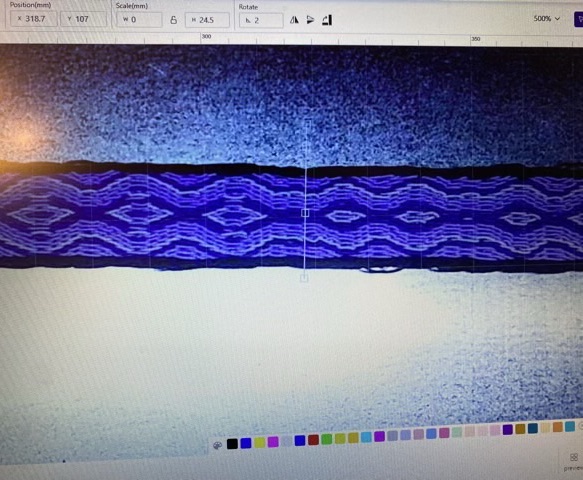

I had at least one decent section, so the next quandary was how to cut it. Ideally, it needed to be cut and sealed to prevent the elastic from unraveling. I happen to have a laser cutter. I couple experiments with settings, and I was able to cut and, in the same process, seal the band.

I put the band on a sheet of steel, and used high power and a slow speed to cut the band. It look a couple of experiments with settings to get a cut with minimal burn.

To protect the end while threading it through the hardware, I wrapped it in washi tape.

Sewing was a little challenging because of the thickness, but this little three-in-one sewing tool was a life saver.

The most unfortunate part of the whole project is that I didn’t realize the slides on the ends have an up and down. I installed them both upside down. Nuts.