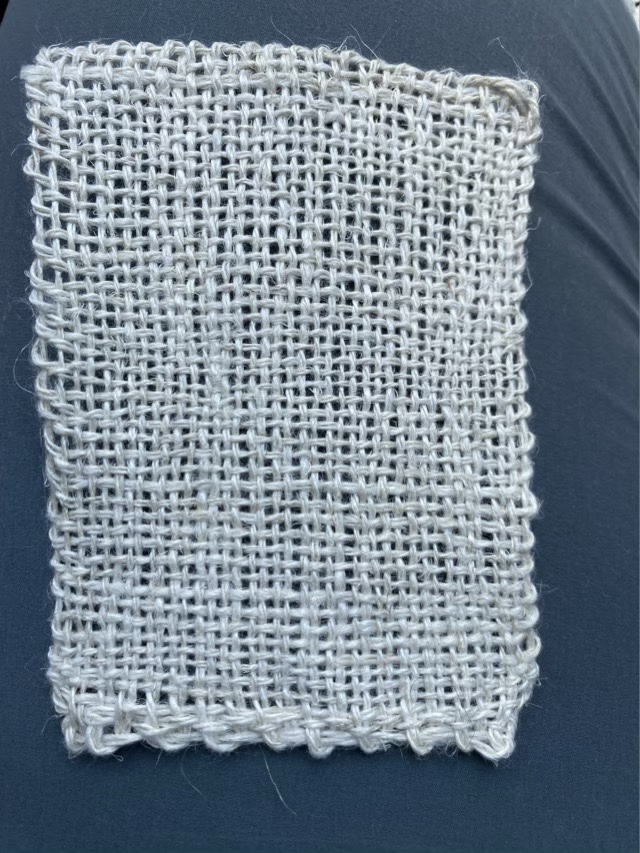

I finished another fiber page (really I did three together, but I’m going to spread it out in this blog). This page is about hemp. The hemp top, combed hemp fibers, came in a collection of plant fibers as a gift from my sister. I spun the singles on a drop spindle, then made a two-ply yarn using a different drop spindle. The fiber was nice to spin, but the resulting yarn was stiff and scratchy, even after setting the twist by boiling. Hemp is usually used to make rope and strong fabrics, certainly not anything you would want next to your skin. I made a knitted swatch with size 4 needles, a crocheted round with size C hook, and a woven sample with four salvages using a Clover mini-loom and doubling the warp threads. Even though I wouldn’t make clothing with this yarn, I think it is the neatest page I’ve done so far.