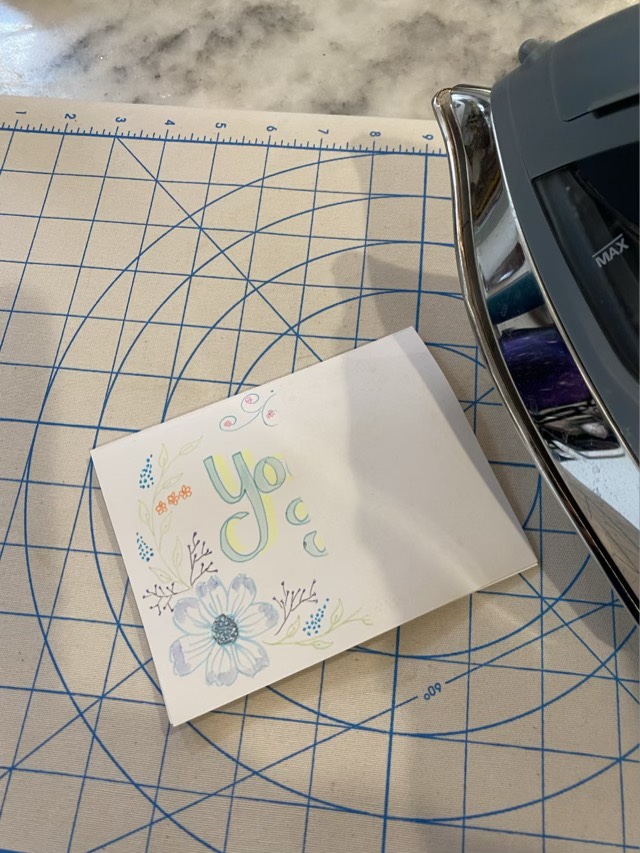

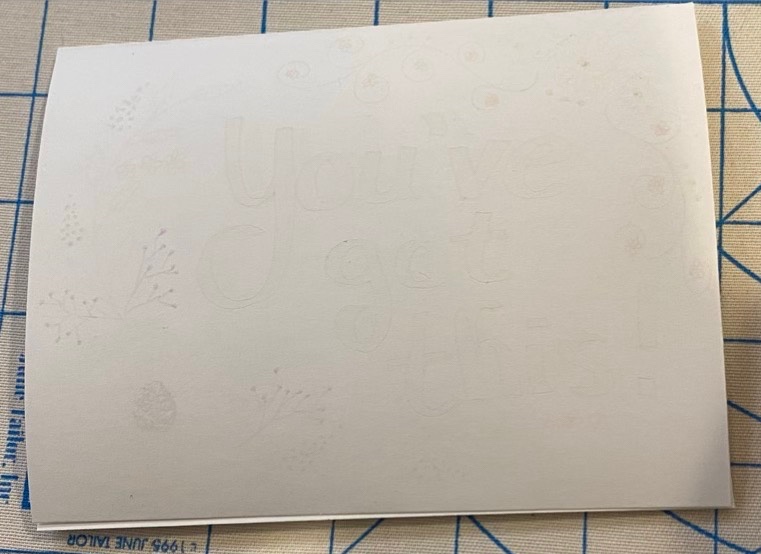

I ran an experiment with my sister. I decorated a card with Frixion pens, markers, and highlighters, then “erased” it by ironing. The way Frixion ink erases is by heat; when you use the little eraser it creates friction with the paper and generates enough heat to deactivate the ink color. Neat. The super cool science geeky part is that if you freeze the paper, the ink reactivates. I tested the card in my own freezer, then heated it again. I’m not sure how many times the ink can be cycled, but I know it is over four (that is how many times I’ve tested it previously before getting distracted). The colors fade slightly in the first cycle, but not much in subsequent activations.

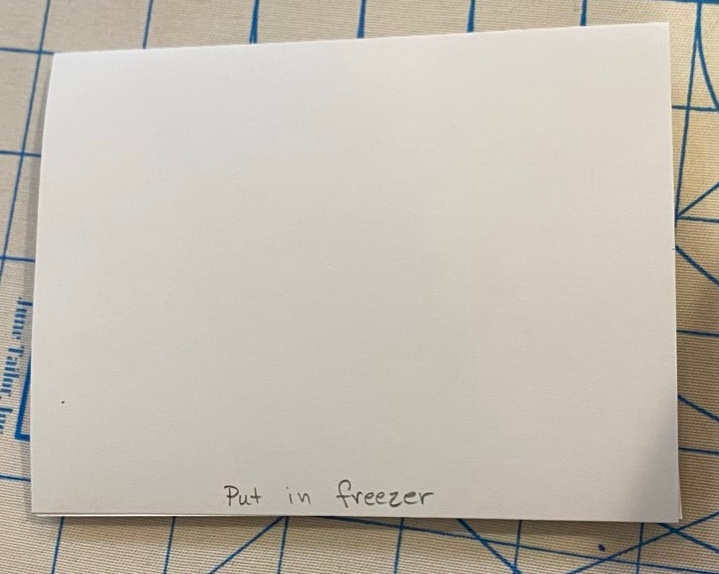

Since the markings don’t erase completely (there are shadows and indents), I did a little misdirection and wrote the instructions on the back of the card. I put it in an envelope and mailed it to my sister. She reported back that it worked! I will have to wait until next summer to send another one; having the card sit in a freezing cold mail box would defeat the trick.

I probably get a bigger kick out of this than is normal for an adult.