Thor the gray tabby made an interesting decision to hang off the side of the rocker.

What he was really doing was waiting for Missy the dog to run by so he could grab her tail.

Thor the gray tabby made an interesting decision to hang off the side of the rocker.

What he was really doing was waiting for Missy the dog to run by so he could grab her tail.

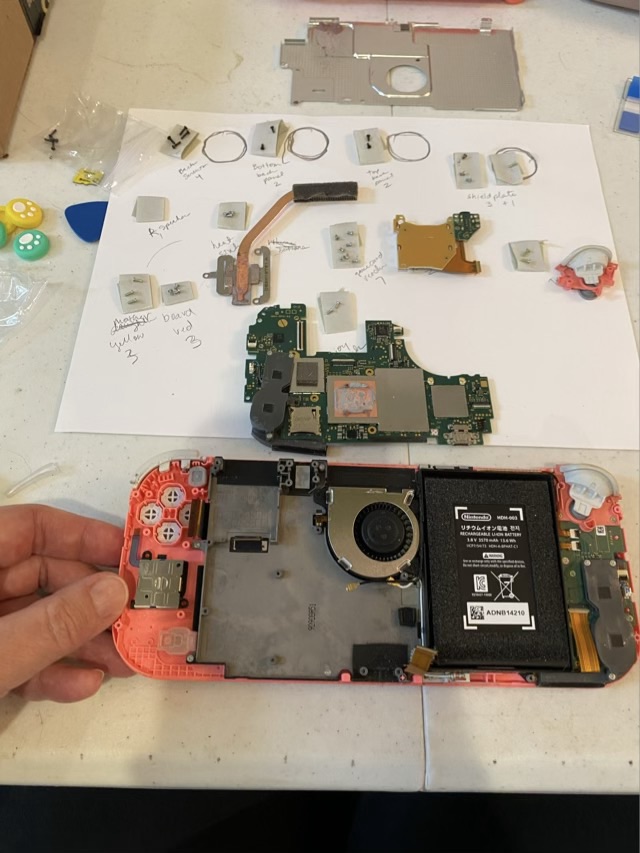

My youngest’s Nintendo Switch lite broke. The left joystick actually flopped around, not just drifted. She received a new to her full size Switch for her birthday, so the old one was a wash. Since it didn’t hurt anything to try, I bought an under $20 joystick repair kit and found directions. The directions had 28 steps just to get the joystick out, then the same 28 steps were retraced to put it back together. The kit came with two joysticks, which looked identical, except for part numbers on the back. There was no indication anywhere which was left, and which was right. I picked one. The disassembly didn’t go too bad for the left joystick, although I did break the left speaker connection because I didn’t realize that the plug was a teeny tiny white part in a slightly larger tiny white socket.

Feeling brave, and while the device was open anyway, I decided to replace the right joystick as well, after all, I had the part. Oh dear. The right joystick is a whole different set of steps, and involves removing a motherboard. I didn’t break the right speaker, and I had to replace the motherboard three times before all the cables were in the right spots, I thought. I missed the fan cable, and when I tried to retrieve it through the motherboard, it tore. Nuts.

Things I learned in this process: don’t force it (honestly I really should have known this, this is not my first rodeo). The engineering and durability of these devices is amazing. If I hadn’t been ham-handed, this is a doable repair. Inverted washi tape rings make great holders for tiny screws. Label everything. I saw my eldest set up for a deconstruction this way with wells embossed into card stock and it is brilliant.

The number one thing I was forcefully reminded of in this project: stop when you’re ahead.

The pieces and parts are now marked for a trip to tech recycling.

I’ve wanted to try finger weaving since I heard about it on a Sprang group (it was misidentified as Sprang). In Sprang, there are no weft threads, the vertical warp threads are overlapped consecutively. In finger weaving the warp threads become the weft threads, similar to braiding, but with more threads. I watched video after video before I found this video showing the weaving going out from the center, which made sense to me, and seemed balanced.

I wasn’t sure how to end the weaving, I’ve seen some bands just knotted at the end, but I want to put it in my fiber book, so the finish needed to be relatively flat. I opted to run two rows of double half hitch knots along the angles of the weave, which I think came out complimentary.

This was an interesting exercise, and finger weaving is a nice addition to my craft repertoire. It is nice that it can be done by anchoring one end, rather than needing a loom, and it comes out thinner and more flexible than macrame. It is more interesting with multiple colors.

Back in February of 2009 I was doing glass fusing in a small Paragon kiln. I was experimenting with fusible glass paint, which is applied with a bottle fitted with a thin steel tube. Colored ground glass is suspended in a liquid medium and placed on the glass, rather than painted with a brush. It is an interesting technique and one that requires a steady hand, a pin to clear the nozzles, and a wipe to clear up the mistakes. I like that these pieces reflect my preference for the Art Nouveau style. After I fused the paint to the clear glass in the kiln, I mounted the glass on acrylic photo frames. (I don’t know why I went this direction, it seems counterintuitive to glue glass to plastic rather than just use a frame. I’m sure there was a reason.)

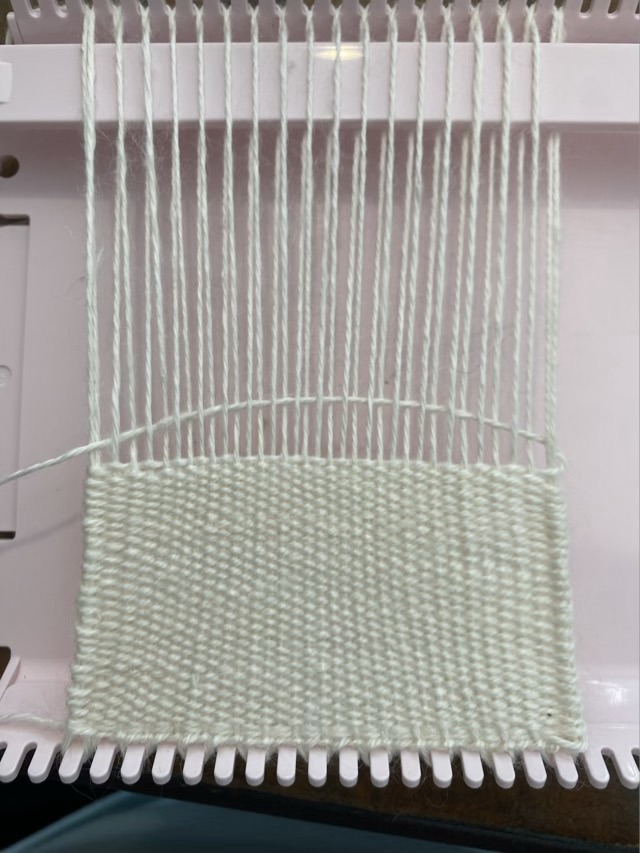

Chain-plying yarn takes a single spun yarn and makes a three ply yarn from one bobbin or ball. The spinner makes long chain links, like in crochet, but each chain can be the length of an arm. There is no waste as the yarn is always tripled to the end of the length. It is a very useful technique especially if the spinner wants to preserve a color gradient, or doesn’t want to waste any precious material dividing the ball into three and risking running out of one ball before the other two. It does leave its mark, though. Each chain has a bend of yarn, a hiccup in the twist of the ply. This is difficult to see in a finished piece, but in a half-woven swatch, the chain loop ends are more obvious in the warp.

These chain bumps are more of a concern if the weaver wants to leave a fringe. I wove in the ends and trimmed them. To fix the missed warp in the weave, I took a small piece of yarn and sewed it over the warp and tied it in the back.

The chain bumps are not readily visible in the end piece, but the edges are uneven, and I pushed the weft into the loops left by the loom, arcing the bottom of the swatch. Which is why I swatch, I learn so much from each piece.