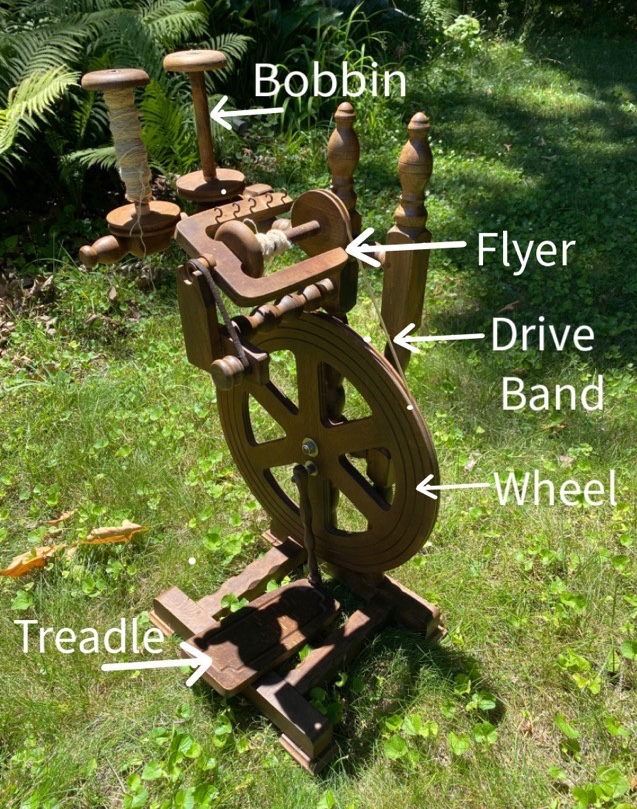

I sat down at my vintage spinning wheel to attempt to produce yarn. I had some lovely dyed roving that my youngest picked out at a weaving store to use. Getting started was a little tricky. Moving the treadle to drive the wheel in the right direction took some practice, then the flyer assembly kept popping out of place. Hm. It seems the support arm for the flyer assembly has sagged over time, making the space about a quarter inch too long. My Dad made me a quarter inch thick wooden washer to put on the flyer side. It worked perfectly!

The way the flyer assembly works is the flyer and the bobbin both spin. The flyer adds twist, and the bobbin winds on the yarn. But they should spin at different speeds. The ratio between the rate the flyer and the bobbin spin gives you how much twist is in the yarn. If everything is working right. I could not get the flyer to slow without stopping, so I went with it. I let the flyer and bobbin spin together to give me twist, then when I was ready, I stopped the flyer and wound the yarn onto the bobbin. It worked to give me yarn! And I had control of how much twist went into my yarn before I wound it up.

I’m still working on my consistency, but I’ve made yarn on a vintage wheel! Huzzah!