Some people who use laser cutters advocate for using masking tape to reduce the smoke stains on the surface of the wood. I tried it as I redesign my dishwasher magnet. I don’t like it.

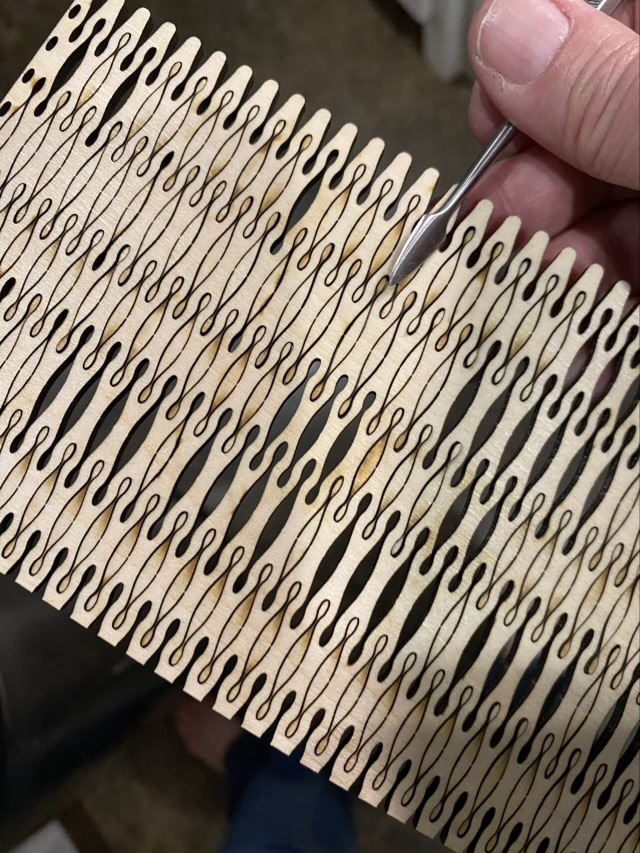

With the addition of the tape, the laser settings have to be increased because of the thickness of the tape. After burning a design there are also small bits of tape left behind that need to be picked off, and in the fill areas the obliterated tape leaves a sticky residue. Yuck.

So how to deal with those smoke marks? A little bit of sanding with 400 grit sandpaper works wonders and takes less time than removing sticky tape.

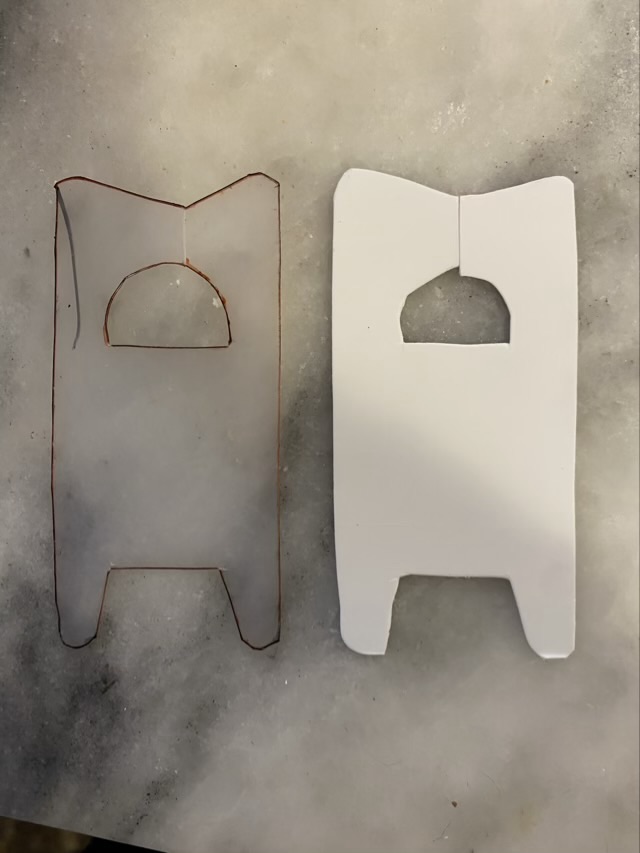

Back to the beginning: Why am I redesigning? I didn’t like how the bit map engrave of the previous design was a little messy and took a long time to engrave, so I redrew the art and made an SVG file, which cut the processing time almost in half. Depending on settings, the previous bit map design took 11 minutes, where the new SVG takes 6.