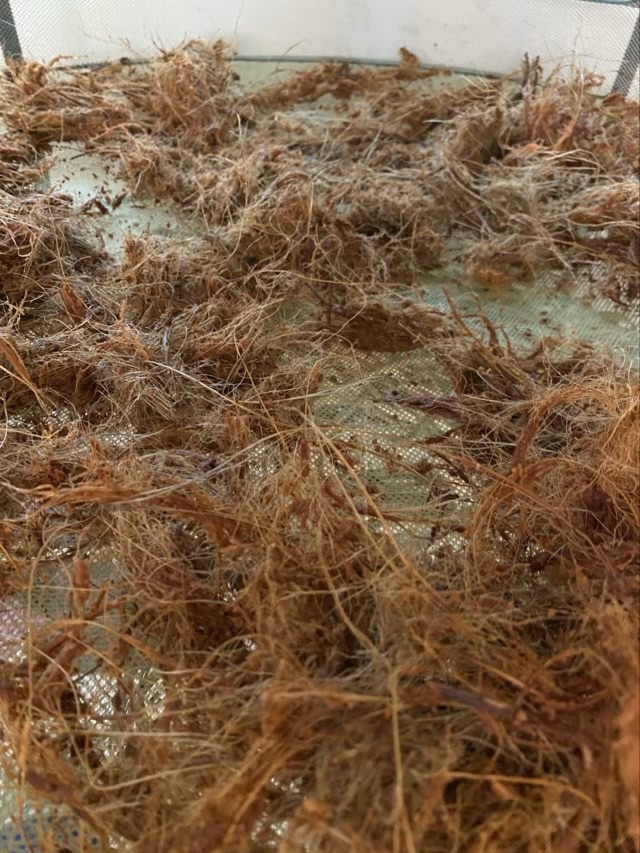

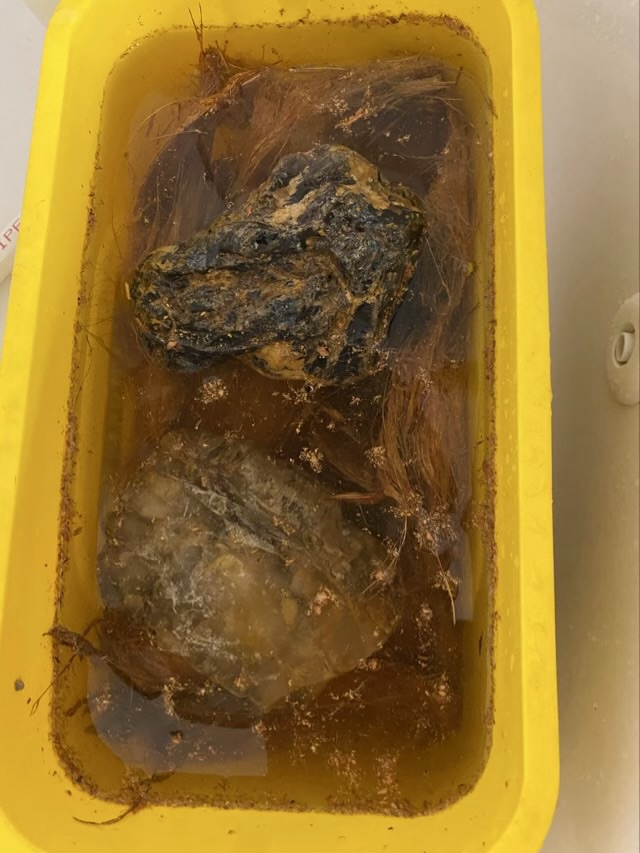

I took my dried coconut husk back outside after soaking it, pulling it apart, rinsing it, and then air drying it on a drying rack inside. The mass of husk was copiously shedding bits whenever the drying rack was disturbed, so outside was the best choice for further processing. I decided to twine the coconut coir, the long, strong fibers from the coconut husk.

Even with the soak and rinsing, there was still a large amount of spongy brown pith on the fibers, which I scraped off with my nails. I separated out the longest fibers, leaving the pith and the short, fine, breakable fibers, which were more difficult to twine.

I was a little disappointed in how few long fibers I was able to rescue, and I’m not sure that the soaking and rinsing really made my work any easier. I have four more white coconuts (unripe), which I will try getting the fibers straight from the husk as a comparison. The coir pith I put in my compost heap, it has excellent moisture retention so will do well in the mix for future plants.