I’ve been cutting yarn bobbins out of waste plastic, as my grandmother did.

I’m not as precise as my grandma, or I don’t take as much time, but I wondered if my new laser cutter could do a precise job for me. I read that the kind of plastic matters. PVC, for example, lets off chorine when heated, which can degrade the laser.

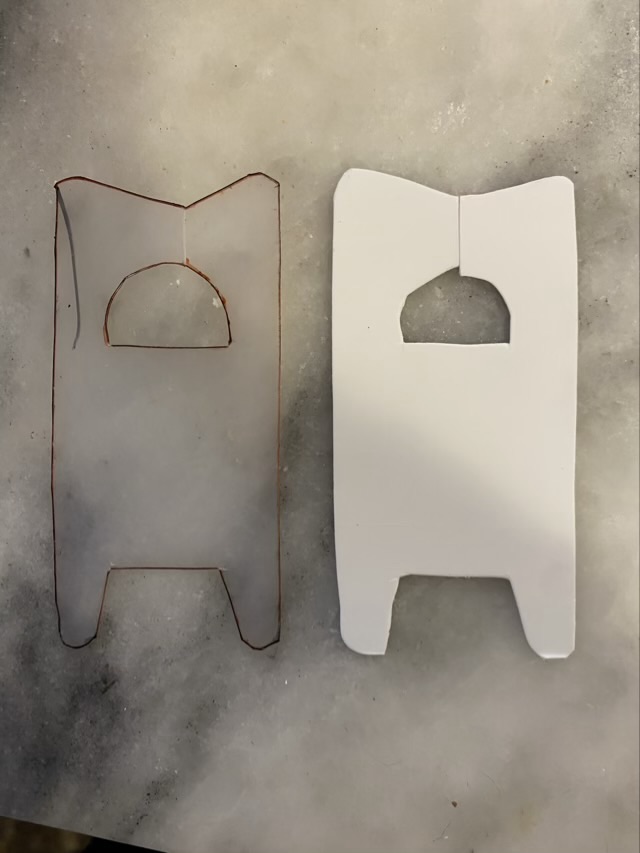

I designed an SVG file of the outline and hole, but left the slit to be cut by hand. The slit needs to be tight to hold the yarn back. I did my first try on a Tide pod container, which is PET (polyethylene terephthalate).

The plastic melted and cooled, resealing the cut, but not releasing the piece from the base material. The cut the nearly made it through showed bad burn marks on the back where the label was adhered. I attempted to remove the label, but it was firmly attached.

The labels on the Tide container have a shiny component, and I wonder if this is why it failed. Hm. Experiments will continue.