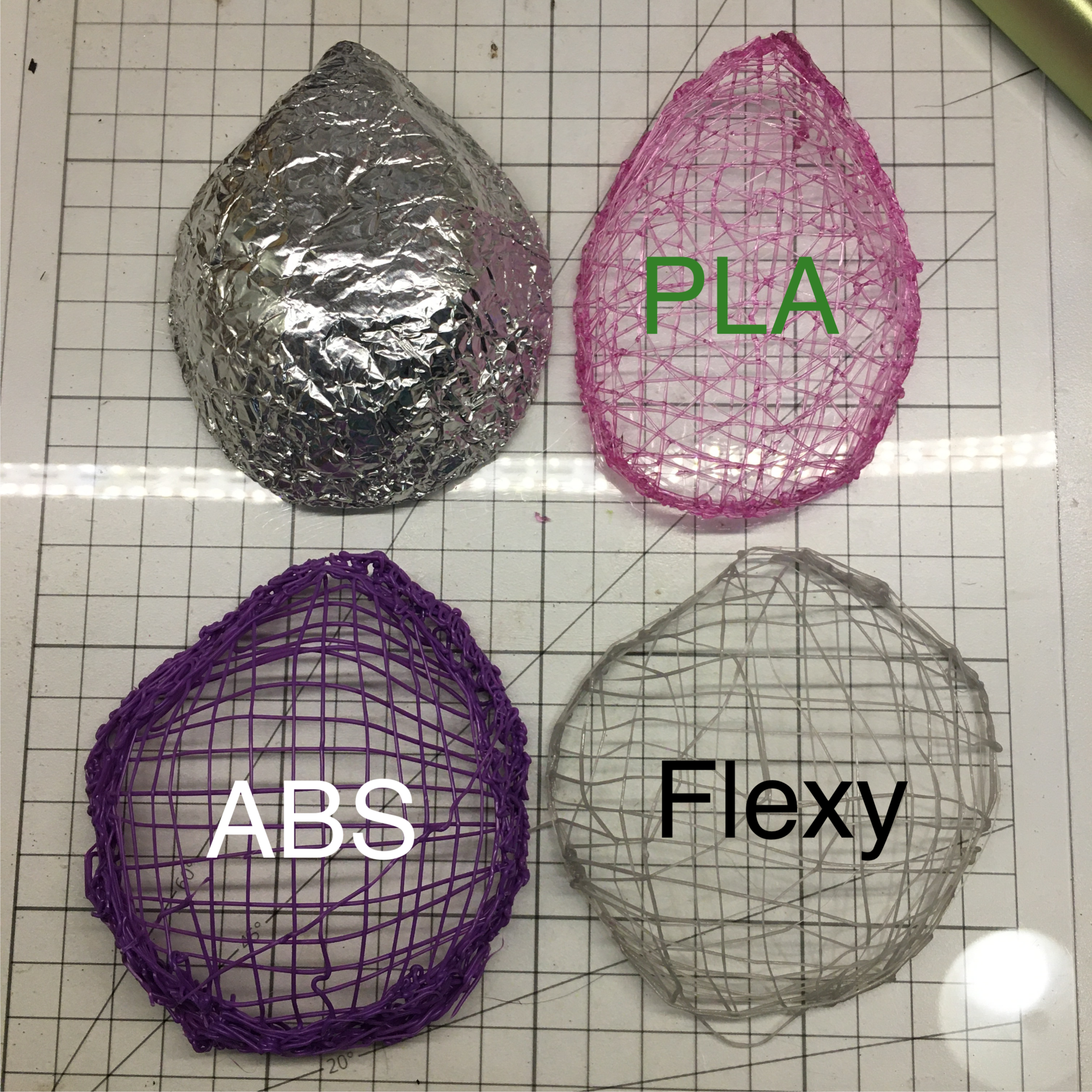

Sometimes things don’t turn out the way you hope. I had a grand idea of making mask frames (to hold the fabric away from the nose and mouth to make breathing a little easier) with a 3D printing pen. I thought this might help my youngest keep her mask on for longer time periods. I was super enthused and ordered all three types of material to test: PLA plastic, ABS, and flexy.

I used a chenille stick and aluminum foil to make a form for the mask. The plastic (PLA) stuck just enough to temporarily adhere to the form, which made forming the plastic easier. The ABS was harder to work with, but I found making small overlapping circles worked better than making long straight strings. The flexy was interesting to work with as the resulting mesh is very flexible, but it didn’t have enough strength to be a frame. I also did some destructive testing, because I would rather know how it breaks before I sew it into a mask. PLA and ABS do break when pressed flat, but not as much in the areas made of overlapped circles. I settled on using PLA and tiny circles, and managed to make and destructively test one frame before the pen broke. Ugh. I decided to just order some from Amazon. Then the first order was lost. Still waiting on the reorder.